A metal products company had a system of multiple compressors arranged in two compressor rooms. The maintenance workers were having constant problems setting up their compressors to run in a logical sequence. For some reason, the main compressor would never turn off in automatic start, which would allow them to save energy. The big compressor […]

Compressed air fail: Remote coolers

A wood products company had issues with its compressor room. Despite installing good filtering, the compressor oil and air coolers would clog up with sawdust — and the compressors would constantly overheat. The maintenance manager, remembering something from one of his previous jobs, decided to move his compressor coolers outdoors. This worked great in the […]

Quality air is critical for aerospace manufacturing

Compressed air quality is crucial for aerospace manufacturing, as aircraft components and tools must be of the highest quality and precision. This demanding standard for component quality urges aerospace manufacturers to utilize compressed air with specific requirements. The air must be clean, dry, and unvaried under pressure. If the air becomes dirty, moist, or varies […]

Reduced price for CAGI exams offered

Are you a compressed air professional who would like to get CAGI Certified? Currently there is a reduced price for writing the Certified Compressed Air System Specialist exam to obtain your CCASS designation. Having this designation is important as it shows you have the knowledge required to be competent in the industry, knowing the general […]

Packaging manufacturer increases uptime with oil-free compressed air technology

Oil-free compressed air is crucial for packaging companies as there is zero tolerance for oil vapor presence in production. For a flexible packaging company serving North America’s food, beverage, and pharmaceutical industries, detecting oil contamination would mean a facility shutting down, resulting in significant production loss and maintenance costs. In addition, if oil traces reach […]

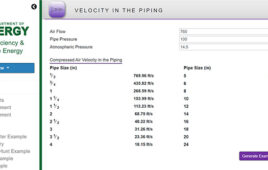

Why is compressed air pipeline velocity important?

How do you determine the diameter of the compressor room header pipe? Many piping installers might take a look at the outlet diameter of the air compressor and chose a similar size, but due to the variety of different outlet sizes, and the combination of flow of multiple compressors in a room this may not […]

EPEQ AIR20 provides dependable air from proven compressor

When you need clean quiet power with no fumes or extensive heat build-up, the EPEQ AIR20 is a proven compressor choice. EPEQ Air Compressors are designed to be ultra-efficient when paired with the ELiMENT Battery. The EPEQ AIR20 reciprocating compressor provides 20 cfm at 150 psi, which is suitable for intermittent air use while performing […]

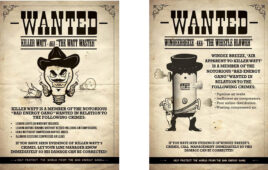

Wanted for criminal waste: Killer Watt!

Did you know that there are criminals hiding in your plant wasting your energy and hard-earned dollars? In fact, they are nasty, terrible creatures who deserve to be tried and convicted. Be sure to hunt them down and arrest their wasteful ways. Remember that all it takes is a little effort — and it could […]

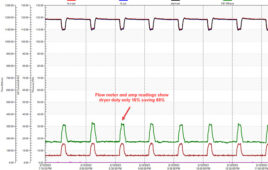

Compressed air: Dewpoint control saves

A medicinal products supply company installed a 600-cfm heatless desiccant dryer to condition their air, due to the nature of their business they wanted high air quality. They also wanted to save energy, so they upgraded this dryer to dew point dependent switching, a control mode that turns off the 90-cfm purge flow when output […]

How do I fix a VSD compressor control gap?

Question: I have a 1,000 cfm VSD compressor, but due to motor and control problems it is producing only 560 cfm. I notice my compressors are fighting with each other. What new size of VSD do I need to fix this problem? Answer: The basic rule in running with a VSD is that the variable […]

ELGi to launch GP35FP portable air compressor at CONEXPO-CON/AGG 2023

ELGi North America (ELGi) plans to introduce the new GP35FP portable compressor at the highly anticipated CONEXPO-CON/AGG 2023, from March 14 – 18, at the Las Vegas Convention Center. At IFPE in booth South Hall 1 S61908, ELGi will display the GP35FP, the latest portable air compressor in the portfolio and the trusted D185T4F model. […]

VMAC’s introduces G30+GEN rotary screw air compressor/generator

VMAC has announced the release of its G30+GEN gas powered rotary screw air compressor/generator, which combines two convenient forms of power into a single, innovative system. VMAC’s G30+GEN provides 25 CFM of compressed air at 100 psi and is designed to maintain max CFM 100% of the time. Operators can quickly switch from compressor mode […]

Hannover Fair panel to focus on compressed air and vacuum technology

Compressed air and vacuum technology is continuously being digitalized, but is digitalization really a panacea when it comes to sustainability and energy efficiency? The international CEO Panel on Compressed Air and Vacuum Technology at Hannover Fair will provide the answer to this question. On April 20, CEOs from global leaders in the industry will discuss […]

Where do you get compressor efficiency information?

Years ago, in the North American compressed air market, it was a free-for-all when it came to compressor ratings. Some questionable efficiency numbers were published, leading customers to believe that they were making good choices in purchasing the most energy efficient compressors. However, as time went on, it was gradually discovered that some published numbers […]

Compressed air fail: Optimized nozzles

A building products company had constantly overheating bearings on some large fans induced draft in their process and decided to use compressed air to provide some extra cooling. On one fan bearing they installed a spare air wand and tied it in position with wires, so the nozzle pointed directly at the hot bearing, this […]

Compressed air fail: One little button

A farm implement manufacturer had a system of three large 150-hp compressors that were air-cooled lubricant-injected screw compressors. To control these compressors — two of which were needed for peak duty on any given day — the compressors were set up in a cascaded pressure band arrangement, with each unit running in load/unload mode. In […]

Compressed air fail: Frozen lines

A wood products company had some troubles operating its compressed air system in the coldest winter months. Maintenance workers found that the pressure at various points in their plant would fall to very low levels, especially after weekend plant shutdowns. The plant had a system of lubricated screw compressors with refrigerated air dryers to condition […]

Compressed air fail: A holiday miracle turns bad

A metal processor had a four-compressor system that was well controlled by a compressor sequencer. System operation was very well monitored by a system of pressure, power, and flow instruments that fed system operating characteristics back to the maintenance supervisor. One day before the Christmas holiday, the supervisor noticed that the variable speed drive (VSD) […]

Compressed air issues: Bag method leak estimator

Have you ever wandered through your plant on a down day and found that it sounded like a pit of vipers with noticeable compressed air leaks hissing away constantly? Have you wondered how much money you are losing because of the leaks? Now you can answer that question armed with a simple trash bag and […]

Compressed air fail: Turn on to save

In the compressed air world, there are quite a number of energy savings features available to be installed on air compressors and air dryers. Often, these cost a premium to buy — but will very quickly pay for the added cost through reduced electricity bills. A recycling facility purchased an energy efficient heated blower style […]

Six simple ways to improve your compressed air system

By Ron Marshall Compressed air is one of the most expensive ways to supply energy to facility tools and equipment. This is due to the inherent inefficiencies in the process of compressing air — the biggest product is heat and the secondary output is compressed air. While this is disappointing, there are still things that […]

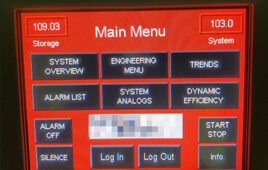

Why is compressor control important?

When controlling screw compressors, the goal is to try to keep all the running compressors fully loaded except one. And the one running partly loaded (called trim) is selected as the one having best part load efficiency characteristics. When there are only two or three compressors in a group, it is quite easy to set […]

Tsunami Compressed Air Solutions announces four new products for 2023

Tsunami Compressed Air Solutions released four new products — adding more capacity and customization to the Air Dryers product line. Tsunami’s new products expand on the existing Pure Series Dryer line and include the Pure-1, a 5-cfm dryer, the Pure-3, a 10-cfm dryer, the Pure-7, a 25-cfm dryer, and the Pure-30, a 120-cfm dryer. All […]

How do you adjust dew point on air dryers?

Question: I need your advice about how to adjust the dew point for the dryers which are equipped with a dew point controller. Also, for those not having a controller, how can we determine which dew point is the best setting — -40 or -70? Answer: This is a complicated question. The method for adjusting […]

Compressed air fail: Ventilation design

A plastics manufacturer was having constant trouble with his desiccant air dryers. No matter what he did, they would constantly set off dewpoint alarms, which was very annoying. He called in a compressed air auditor to have a look. The auditor shot temperatures and found that the discharge of the compressors was too hot. Outputs […]