VMAC surveyed 340 people in the service truck industry in 2022, asking them questions about their fleets and service truck equipment. The data shows 80% of professionals prefer rotary screw air compressors over reciprocating air compressors on their service vehicles. The 2021 and 2020 survey results also indicated a strong industry preference for rotary screw […]

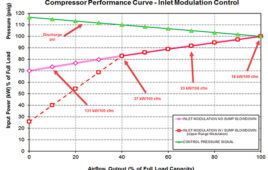

Compressed air fail: A modulation nightmare

John, the maintenance manager of a wood products company, was very proud of his Number 3 compressor. It has been operating for years, racking up more than 200,000 run hours — and was so trouble free, it was almost scary. Of course, John kept it maintained, changing oil and filters on a regular basis, fixing […]

ELGi announces rebranding of portable air compressor line in North America

ELGi Compressors USA Inc. (ELGi), a subsidiary of ELGi Equipments Limited, a compressor manufacturer, announced the strategic rebranding of its portable air compressor line in North America, previously branded as Rotair. ELGi acquired the Italian-based portable air compressor manufacturer, Rotair, in 2012. Rebranding “Rotair” to “ELGi” will strengthen the company’s presence in the North American […]

Compressed air fail: Fire system

A large industrial plant fell on hard times and had to reduce their production shifts to only 8 hours per day, 5 days per week. The compressed air system remained running full time 24 hours a day, including weekends, due to the need to supply the plant’s dry fire system with air pressure. The total […]

Should I repair or replace my aging air compressor?

What should you do when it comes time to decide if you should repair or replace your aging air compressor? There are a few things you should consider. Air compressors are like motor vehicles — if they are used continuously, hardly shutting down, they should not be expected to run for a long time without […]

Why are compressed air temperature ratings important?

Question: My compressed air dryer is rated at 100° F inlet air temperature. What will happen if the air temperature is lower than this? Answer: Having the air temperature lower than the dryer rating is a good thing. Actually, dryers are commonly rated at 100° F inlet temperature, 100 psi and 100° F ambient temperature. […]

Compressed air: A bike tire analogy

Running out of pressure? Think about storage volume. Consider this — remember when you had your 10-speed bike with those thin tires? You could ride quite fast, but when it came to filling up the tubes to the proper pressure. all it took was a small shot on the fill valve to change the pressure […]

Compressed air fail: Dusty filters

A sawmill ran a set of six large air-cooled compressors to feed their various processes. To cool the compressors, the air was drawn from outdoors and mixed with indoor air to keep temperatures from freezing the compressors in winter. This facility has a tough environment for cooling air because of the sawdust. To attempt to […]

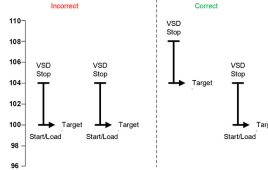

Are two VSD compressors a problem?

Question: I’m a compressor salesperson. Lately, the large building tenders we’ve seen have been spec’d for two variable speed screw compressors to run together sharing the load. This would make sense to me if one was a 100% backup and they never ran together, but that does not seem to be the case. Everything I’ve […]

Compressed air fail: A forgotten step

A large industrial company was having problems with its air quality. Water was appearing as if at random at one of its most critical processes, causing instrumentation failures and contamination of the product. This issue was difficult to understand because it looked like the refrigerated air dryer was working fine — and dewpoint looked good […]

Coval announces enhanced multi-stage vacuum pumps for heavy duty suction

Coval’s new CMS HD series of modular multi-stage vacuum pumps offers a solution for high suction flow rate vacuum handling of a wide variety of objects. The pumps are ideally suited for pick-up and transfer operations in applications such as handling of porous parts or emptying large-volume tanks. Jointly developed with system integrators and industrial […]

How do you flow test an air compressor?

As compressors age, there can be internal wear or control problems that affect the flow output capacity. Often times, observing the amps of the compressor — and comparing that to the motor nameplate — can show if a compressor has problems. If the amps are low, that usually means the compressor flow capacity is lower […]

Compressed air fail: Two flow meters

There is an old saying about a man with two watches who never knows what time it is. One wonders if this applies to having two flow meters? Fig. 1 shows the comparison of two thermal mass flow meters measuring the same compressed air stream. We can see there is a disparately between the readings, […]

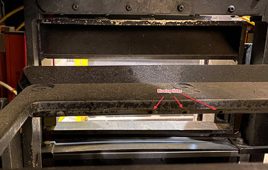

Compressed air fail: Air water cooling

Desperate times call for desperate measures — or at least that is what the maintenance personnel at a chemical plant thought when they had production outages caused by overheating of their water-cooled, lubricant free compressor. So, they rigged up some cooling using a compressed air powered ring jet nozzle (Fig. 1) and directed a flow […]

Atlas Copco acquires compressor distributor in New Mexico

Atlas Copco has acquired the operating assets of the compressor business of Mesa Equipment & Supply Company (Mesa) located in Albuquerque, New Mexico, and 19 employees will join Atlas Copco. The company sells oil-free and oil-injected compressors and offers parts and services across a broad range of customer segments. “Mesa has built a strong sales and […]

Compressed air fail: Dryer signature

A compressed air auditor placed data loggers on a single compressor system with a fixed cycle heatless desiccant dryer. The pressure at the compressor discharge and dry storage tank was also measured, along with the compressor input amps. On examination of the system profile, it was determined the compressor was rapid-cycling due to lower than […]

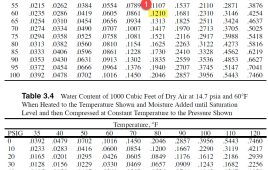

Compressed air fail: Drains importance?

Question: On our air compressor, we have a drain at the bottom of what looks like a filter, located after the air cooler. The drain failed so we turned it off … how important is it anyway? Answer: Here is the data you need to know about condensed water flow in compressed air systems (taken from […]

VMAC Releases UNDERHOOD 40 Air Compressor For Mercedes-Benz Sprinter Van

VMAC has released the UNDERHOOD40 – Van Series for 2022 Mercedes-Benz Sprinter vans with a 2.1 L turbo diesel engine. This latest UNDERHOOD40 rotary screw air compressor is engineered specifically for 2019 to 2022 Sprinter vans and produces up to 40 cfm of continuous air at 100 psi (150 psi max). “As customers upgrade their […]

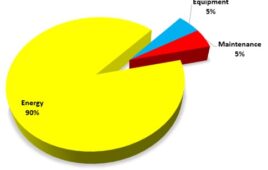

What is VSD cooling?

In the compressed air world, the hottest thing in the market lately has been the introduction of variable speed drive controlled compressors. Being hot (as in popular) is good — but being hot as in temperature is not so great. These units, if installed appropriately, can stabilize the air pressure, and save significant amounts of […]

Robots, cobots, pneumatics, and the future

At this week’s National Fluid Power Association event, the annual International Economic Outlook Conference, Donna Ritson of DDR Communications shared results of an industry survey done for PMMI that looks at the future of robots and cobots for automation. Ritson’s firm had discussions with the leading robot manufacturers, robot suppliers, and integrators in the industry…

Why is flow meter contamination important?

Thermal mass flow meters are excellent devices to use when measuring compressed air flow. These devices use a hot wire anemometer method of measuring the velocity of the compressed air in the pipe. Two probes are used, one heated and the other not, and are inserted into the compressed air pipe. The flow of air […]

Compressed air fail: Units conversion

Have you heard the story of the Gimli Glider? An Air Canada flight ran out of fuel on July 23, 1983, at an altitude of 41,000 feet, midway through the flight. The cause? It was a mix up of pounds and kilograms when calculating the weight of fuel to load for the flight. (Give it […]

Compressed air fail: Cycling dryer savings

Your equipment controls can sometimes tell you some good stories if you observe carefully. And sometimes tell of problems. Consider two thermal mass cycling air dryers installed in a foundry. Thermal mass cycling dryers are designed to reduce the energy consumption of the internal cooling system by turning off and on (cycling) the refrigerant compressor […]

Compressed air fail: Blowing reduction

It is very common in an industrial facility to have compressed air blowing applications installed at various locations to provide cleaning of sensing eyes and scanners. But it is important to keep in mind that this blowing demand can add up quickly — especially if there are many of these applications installed within the plant. […]

Why is condensate disposal important in compressed air systems?

A wood products company had a two-compressor system installed on a mezzanine. Under the compressors and dryers were the piping and storage receivers. Each tank and each compressor had timer drains installed to expel the condensate that forms when the compressed air cools in the compressor aftercooler, piping, and storage vessels. The outlets of these […]