A medicinal products supply company installed a 600-cfm heatless desiccant dryer to condition their air, due to the nature of their business they wanted high air quality. They also wanted to save energy, so they upgraded this dryer to dew point dependent switching, a control mode that turns off the 90-cfm purge flow when output dew point levels are below -40° F.

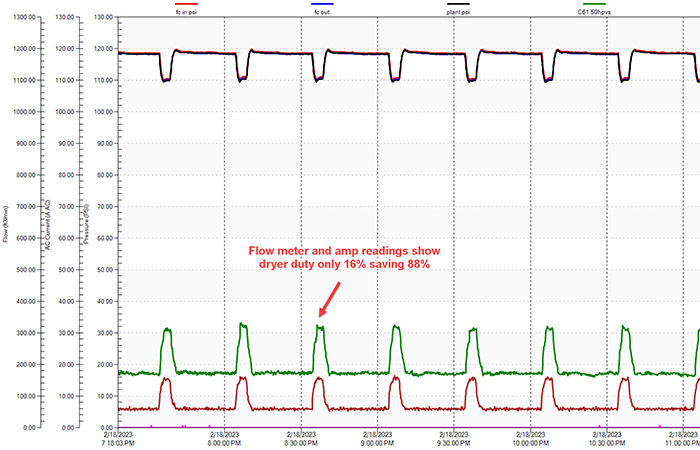

A compressed air auditor installed data loggers on their system to try to determine if they were actually saving money due to the upgrade. Fig. 1, above, shows the result. This screen shows the profile on the weekend where the flow is only 70 cfm. The dewpoint control reduces the dryer purge, rather than consuming a constant 90 cfm the purge only flows about 16% of the time. Estimated savings during this period is 88%.

Based on the system average of 240 cfm flow during the weekly profile, the estimated savings achieved for this upgrade is worth $9,000 per year. Not bad for a $4,000 dryer upgrade! This control mode should be considered when purchasing any heatless desiccant dryer.

Filed Under: Components Oil Coolers, Compressed Air Technologies, Pneumatic Tips