Hannover Messe is one show where you’ll see a lot of new product releases. Here’s a sampling of what we’re seeing:

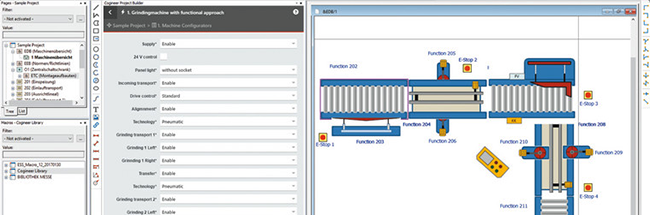

EPLAN Cogineer, an innovative new development to automatically generate schematics, is celebrating its premiere here. SVP of Product Management and Development Dieter Pesch said, “We’ve developed a solution that is easy to use and yet very innovative as regards functionality.”

A mechatronic rulebook and configuration interfaces can be put together intuitively and quickly–without knowledge of any high-level programming languages. This is advantageous for users … experience with the use of macros suffices. It’s the macros that serve as the basis for creating the sets of rules. It doesn’t matter if schematics are generated based on the functional structures or from the system-specific perspective. EPLAN Cogineer meets every user where he or she is right now and requires no changes to how they do engineering.

“100% data continuity from design to construction allows EPLAN Cogineer users to precisely process customer projects in this area without delay,” Pesch said. “And it does this completely independently of the people involved in the process.” EPLAN Cogineer’s essential features are clear time savings due to automatic schematic generation while increasing quality through error avoidance.

EPLAN Cogineer can generate complete electrotechnical documentation with one click. This ensures error-free implementation of the defined rules and structures, thus guaranteeing high quality documentation. Additionally, substantially more projects can be developed in the same amount of time than was the case with the copying and pasting of pages and macros. EPLAN Cogineer offers absolute data continuity from product structuring through to the specific project implementation and supports compliance with norms and standards. This ensures the greatest possible precision and maximum efficiency. The first project can be generated within just a short period of time thanks in part to the intuitive user interface.

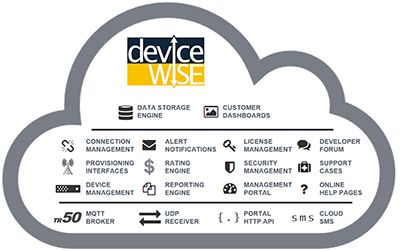

Meanwhile, Telit announced its cooperation with Freudenberg IT on industrial device management, using the Telit deviceWISE IIoT platform. The cooperation between the two companies will focus on transforming the business service and offerings of manufacturers, enabling them to capitalize on all the benefits of Industry 4.0. With Telit’s software platform technology and Industry 4.0 know-how, paired with FIT’s integration and implementation expertise in the industrial market, manufacturers can digitize their entire supply chains with ease.

Meanwhile, Telit announced its cooperation with Freudenberg IT on industrial device management, using the Telit deviceWISE IIoT platform. The cooperation between the two companies will focus on transforming the business service and offerings of manufacturers, enabling them to capitalize on all the benefits of Industry 4.0. With Telit’s software platform technology and Industry 4.0 know-how, paired with FIT’s integration and implementation expertise in the industrial market, manufacturers can digitize their entire supply chains with ease.

“We are extremely proud about our mutual go-to-market strategy with Freudenberg IT because of their best-in-class expertise in developing Industry 4.0 solutions. Our complementary offerings provide FIT with real-time manufacturing data, allowing them to offer Industry 4.0 transformation to end customers,” said Jens Schmolik, Sales Director IoT Services DACH, Telit. “The Telit deviceWISE IIoT platform, with its ability to connect any device to any application, together with the FIT shop floor suite, gives manufacturing companies an easy onramp to the IoT which results in a very fast time to market.”

By using the deviceWISE IIoT platform and the Cloud-based Telit IoT Portal, Freudenberg IT can generate data from devices, machines and programmable logic controllers from all major vendors and make that data immediately available to backend systems, such as SAP. In addition, deviceWISE offers the broadest library of pre-configured drivers for Modbus, OPC DA/UA and other communication protocols, thereby minimizing custom development and coding for faster and easier deployment.

“Looking at the current digital readiness of mid-size and large production companies, it is extremely important for most of them to implement truly success-oriented and holistic IoT approaches right now. Our new partnership with Telit is a perfect example for how to cooperate in the interest of customers. Together we make IoT success tangible,” said Horst Reichardt, CEO Global, Freudenberg IT.

And lastly, Tetra Pak is transforming its Services with the use of the latest digital technologies. The company launched a suite of new services that focus on improving the ability to predict machine errors, accelerating response times, and giving the customer faster, direct access to Tetra Pak’s global expertise.

And lastly, Tetra Pak is transforming its Services with the use of the latest digital technologies. The company launched a suite of new services that focus on improving the ability to predict machine errors, accelerating response times, and giving the customer faster, direct access to Tetra Pak’s global expertise.

Dennis Jönsson, President and CEO of Tetra Pak said, “Digital technologies are revolutionising every industry, and it’s exciting to make the latest innovations work for our customers. We are pleased to be the first to launch digitalised services, offering customers reduced costs, enhanced efficiency, and peace-of-mind. This is just the beginning of what promises to be a very exciting journey for us and our customers.”

Tetra Pak’s new service solutions center around three areas:

• Connected workforce—Empowered with wearable technology, local Tetra Pak service engineers at customer sites can connect directly with company specialists wherever they are, providing real-time, expert support to customers

• Advanced analytics—Data from filling lines around the world is collected into a central database from where it can be accessed and analysed by a team of the company’s global experts. The database means advanced analysis can be used to predict issues and optimise machine performance

• Connected solutions—All equipment at the customer plant can be connected to the Microsoft Azure cloud system (managed by Tetra Pak), enabling machines at different production stages such as processing, filling and distribution to communicate with each other and synchronize. This will give the customer an overview of the plant and offer performance optimisation opportunities for the whole production

Filed Under: Mobile Hydraulic Tips