Parker Hannifin has completed its range of direct operated proportional DC valves with the new zero lap spools for the D1FC/D3FC series introduced last year. This option makes the use of the valves for closed loop controls possible.

Parker Hannifin has completed its range of direct operated proportional DC valves with the new zero lap spools for the D1FC/D3FC series introduced last year. This option makes the use of the valves for closed loop controls possible.

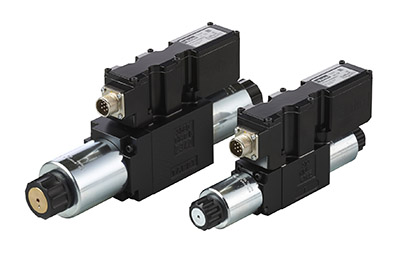

Parker is positioning its direct operated valve series with high dynamics and high volumetric flows between the established D1FB/D3FB series for medium-performance applications, and DFplus valves from the D1FP/D3FP series for the highest performance requirements. The most important innovation for the D1FC, in nominal size NG06, and for the D3FC in nominal size NG10, is a position feedback system which—unlike comparable valves from other manufacturers—is completely integrated in the housing.

The direct coupling of the sensor to the spool also facilitates precise control of the spool position. Thanks to the integrated position feedback sensor, there is no need for an exposed cable connecting to the position control; this alleviates the risk of potential faults through inadvertent breaking of the connection.

The robust, compact valves stand out with their new zero lap spools as well as their high dynamics and repeat accuracy in closed loop controls. This configuration is suitable for a whole range of industrial applications, for example for precise regulation in pipe bending machines and presses or for water turbine controllers. In addition, the D1FC and D3FC can also be implemented for other demanding controlled applications such as break forming presses as well as sheet metal processing machines and injection molding machines.

Thanks to the inbuilt digital electronics, the valve parameters can be flexibly adapted to a wide range of applications. For ease of adjustment, an updated version of Parker’s ProPxD parameterization software is available for free download at www.parker.com/propxd.

Filed Under: Mobile Hydraulic Tips, Valves & Manifolds