Although some manufacturers are moving away from pneumatics in their machine designs, the industry can continue to grow if done smartly. That is, seamless integration of automation and pneumatics will rely heavily on the continued adoption of smart technologies, data collection and use, and more compact, efficient machines. This, said Donna Ritson of DDR Communications in her presentation, “Pneumatics in Automation 2018: The Evolution of Advanced Automation” at the NFPA’s IEOC in August, is how pneumatics technologies can continue to advance over the next decade.

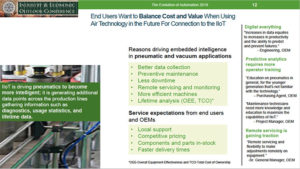

Ritson, who conducted the report for the PMMI and NFPA, said that the main drivers of this growth of intelligence in pneumatic vacuum applications will continue to be the need for good data collection, preventive maintenance measures, less downtime, remote servicing, more efficient machines and more.

Ritson, who conducted the report for the PMMI and NFPA, said that the main drivers of this growth of intelligence in pneumatic vacuum applications will continue to be the need for good data collection, preventive maintenance measures, less downtime, remote servicing, more efficient machines and more.

“We looked at this from the standpoint of a greater level of automation — what are they looking for? They need intuitive and interactive HMIs that go hand-in-hand with the fact that they have less skilled labor; they want simpler machines. They want it to be intuitive so that when someone comes up to a machine there’s now going to be alerts and alarms that help them with their preventive maintenance,” Ritson said. “They want smarter sensors that are going to tell them when a component is reaching its end of life. Everything needs to be more intuitive.”

Automation, said respondents to DDR’s survey, is being driven by the technologies that allow the IoT to accomplish productivity gains — which means pneumatics and vacuum components must have predictive analytics, wireless connectivity, and remote monitoring. And, she added, manufacturers need smaller footprints. “Adding more equipment is not necessarily easy,” she said. “They’ve got to think of creative ways of how do we bring more into a space that’s already congested, with robust feedback.”

Automation, said respondents to DDR’s survey, is being driven by the technologies that allow the IoT to accomplish productivity gains — which means pneumatics and vacuum components must have predictive analytics, wireless connectivity, and remote monitoring. And, she added, manufacturers need smaller footprints. “Adding more equipment is not necessarily easy,” she said. “They’ve got to think of creative ways of how do we bring more into a space that’s already congested, with robust feedback.”

When asking “How dependent are your operations on compressed air?” Ritson noted that 90% said it’s one of the most important things in their manufacturing facilities. It’s definitely not going away, but manufacturers say they need help with air leaks, repeatability, and consistent performance. Pneumatic vacuum components must continue to be more durable, robust, energy efficient, and must be easily available with on-time delivery. Pneumatics must continue to offer better precision, be smoother, be easier to use, increase motion and speeds, and it needs to be more compact, easier to maintain, and above all else, repetitive.

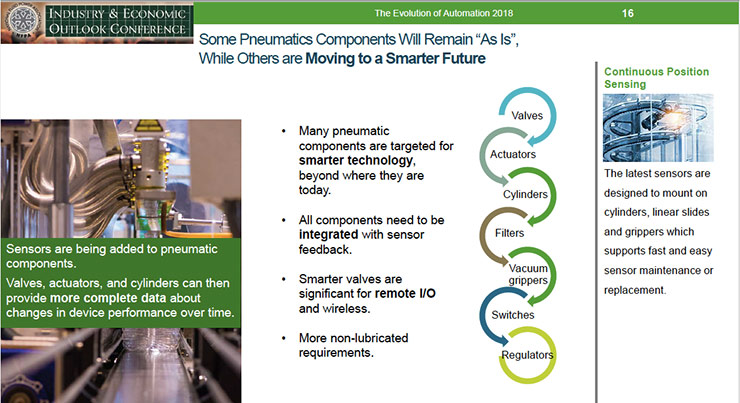

“Continuous position sensing is something the latest sensors are designed with now, to mount on the cylinders and linear slides and support fast and easy maintenance and replacement,” she said. What’s interesting, Ritson added, is that all the technologies that were mentioned by respondents are already developed. “It’s really that whole education process — the technologies’ suppliers say one of their biggest challenges is to educate the industry that that technology is available for them. Embracing automation and having smarter machines on the plant floor is where it’s going.”

Filed Under: Pneumatic Tips