By Josh Cosford, Contributing Editor

Three-way valves, common and versatile tools in fluid power, demonstrate their precision by effectively diverting, selecting, or mixing three flow paths as the circuit requires. These valves, available in lever or solenoid actuation, are widely used for directional control. Their construction style varies, ensuring suitability for diverse applications. The three-way valve, a machined body with three ports, is a testament to their precision and adaptability.

The most common three-way valves in hydraulics are ball valves, cartridge valves and stackable solenoid valves (like ISO 4401 standard). Ball valves may come to mind for some when you think about a 3-way valve. They consist of a three-ported body, cast brass for low pressure use or machined steel for high pressure operation. Like any fluid power component, they are manufactured with any of the common fluid connection standards.

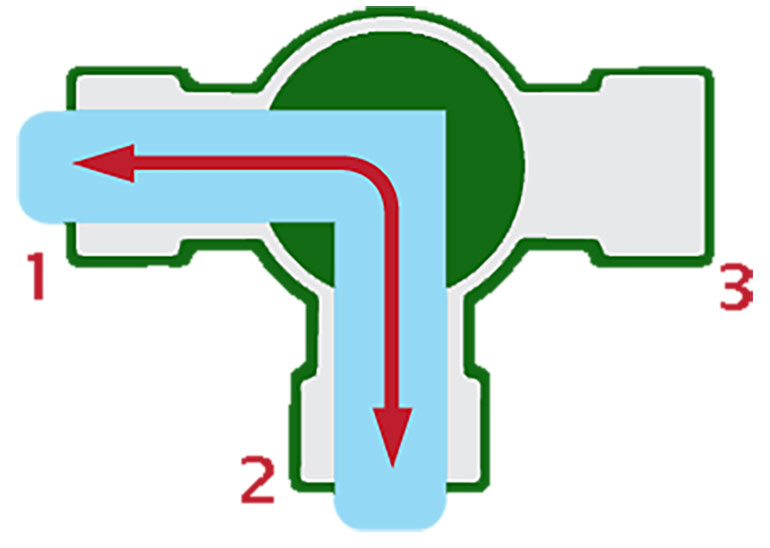

Figure 1. Three-way hydraulic valve

Inside the 3-ported body is a ball cross-drilled with 90-degree holes to provide an L-shaped flow path (Figure 1). The image shows an open flow path from port 1 to port 2, where the fluid is free to flow bi-directionally. By rotating the lever, we can change the bi-directional flow path to ports 2 and 3. In some cases, manufacturers offer a sweet spot where turning the lever 45 degrees blocks flow entirely.

Functionally, a three-way valve is a practical solution for diverting flow incoming from port 2 to either port 1 or port 3, as required. For instance, if you have a single hydraulic pump operating two entirely different downstream circuits, a three-way valve can efficiently manage the flow. Similarly, it can collect flow as required from either port 1 to 2, or from port 3 to 2. This versatility is particularly useful in applications such as selecting between reservoirs filled with different fluids or choosing between two pressure signals to be measured at port 2.

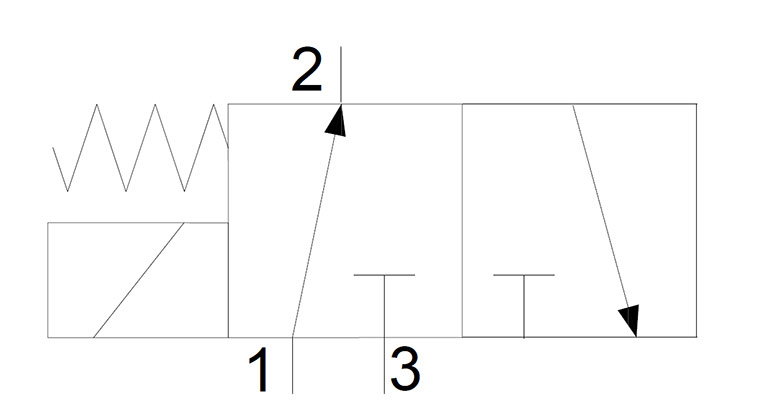

Solenoid-operated hydraulic valves, more succinctly called three-way, two-position valves, are also a common sight. Their physical manifestation takes many forms, such as cartridge valves, subplate-mounted valves, inline valves or custom configurations, but they can all be represented by symbols similar to the one in Figure 2.

Figure 2. Schematic of three-way hydraulic valve

What you see is a 3-way, 2-position valve with solenoid operation and spring offset. In the neutral position, fluid flows from port 1 to port 2, while port 3 remains blocked. When the solenoid activates, it pulls the right envelope to the left, where port 1 is now blocked while allowing free flow from port 2 to port 3. When the electrical current is removed from the coil, the spring bias pushes the left envelope back again.

Such a valve may operate a single-acting cylinder, where turning on the pump extends the cylinder while switching the valve retracts it. Manufacturers produce many versions of this valve, so the ports may also flow bidirectionally through the ports. Other options may include flow between ports 1 and 3 or perhaps a second solenoid to allow 2-position detent functionality.

There are other unique methods to take advantage of three-way valves, such as how two valves may replace a single 4-way, 3-position valve while offering unique advantages such as venting one cylinder port while the other remains closed. Three-way valves offer designers a versatile toolbox option and should be considered a solid option for unique circuits.

Filed Under: Components Oil Coolers, Engineering Basics, Technologies, Valves & Manifolds