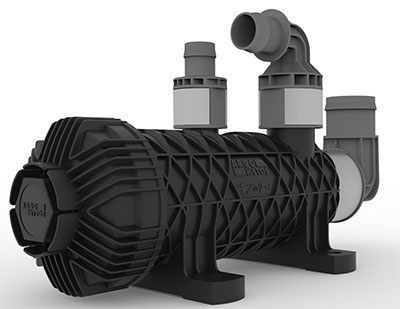

Argo-Hytos 2-in-1 suction return filter

In tractors with a mixed response common oil circuit for transmission and power hydraulics, a suction filter is usually used to protect the pump and a return filter to ensure oil cleanliness. To protect the system during cold start, a coarse safety screen is often also installed in the suction line, but this a disadvantage of this design is that the two filters in the suction line have a negative effect on the cold start performance. In addition, the use of at least two filters results in high cost for the first fit as well as spare parts costs. Combining a suction filter and return filter in one housing — such as the 2-in-1 filter from Argo-Hytos — can reduce these cost and improve cold start performance.

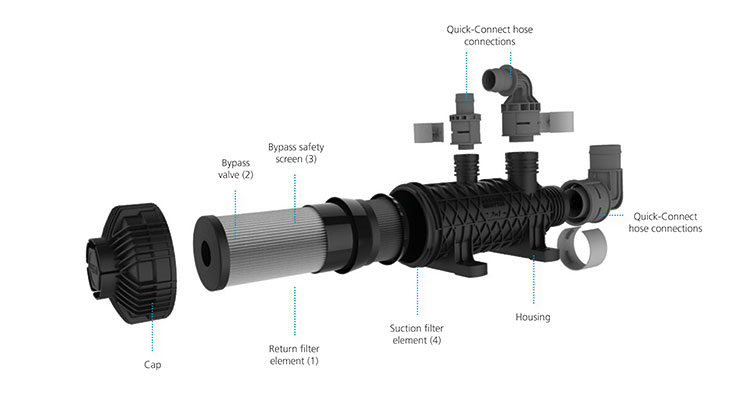

Oil coming from the working hydraulics flows through the return filter element (1) and is directly supplied to the pumps. If the working hydraulic system feeds less oil into the return line than the pumps need to supply, the pump draws the amount of oil needed from the tank via the suction filter element (4). The protective screen (3) prevents coarse particles from entering the system when the bypass (2) is open.

Argo-Hytos 2-in-1 suction return filter exploded view

The housing of the new 2-in-1 filter is equipped with the Quick-Connect system. This allows quick and easy installation of the hoses to the filter housing. The customer can choose from more than 20 different connectors with different sizes and shapes.

This innovative filter concept is particularly suitable for hydraulic circuits such as those in small and medium-sized tractors.

It offers nominal volume flow of 140 lpm in the suction line, 100 lpm in return line and 40 lpm in tank line. It offers long life which can be attributed to Argo-Hytos’ ExaporMax2 filters. It is available with filter fineness of 16 μm(c) in the return filter, 100 μm(c) for the suction filter, and 280 μm in the bypass protective screen.

Argo-Hytos

www.argo-hytos.com

Filed Under: Sealing & Contamination Control Tips