Pressure is simply the force applied perpendicular to the surface of an object per unit area over which that force is distributed. However, there are many ways to reference and identify pressure, which is largely dependent upon the application.

Pressure is simply the force applied perpendicular to the surface of an object per unit area over which that force is distributed. However, there are many ways to reference and identify pressure, which is largely dependent upon the application.

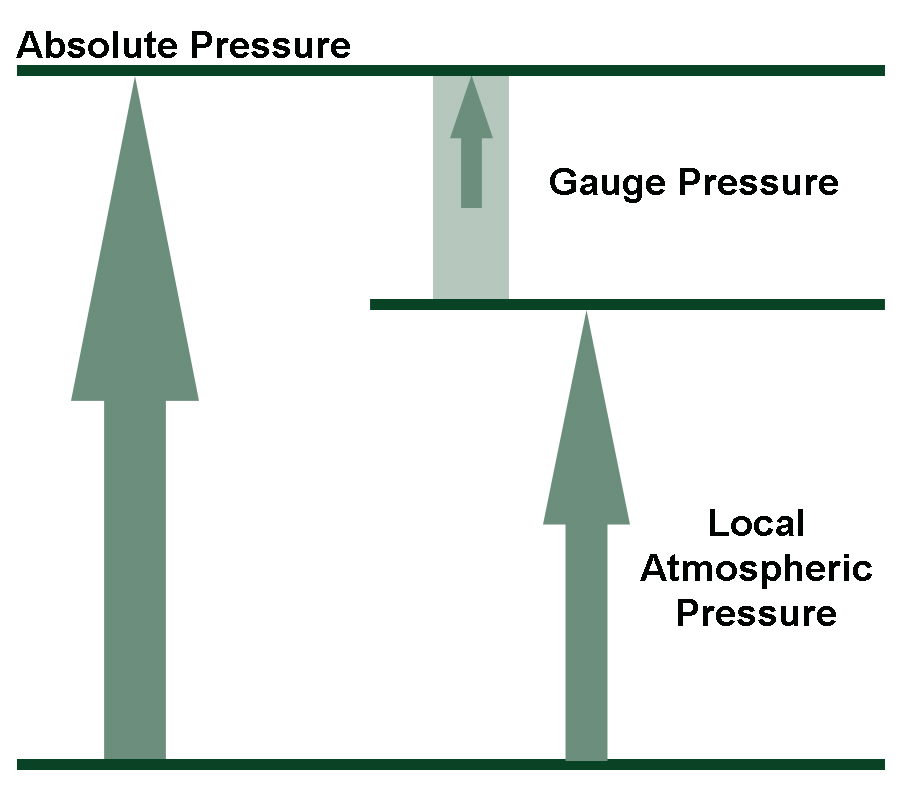

In many applications, there is a common misconception that all pressure measurement needs to be absolute. While there are certainly applications in which absolute pressure measurement makes sense, most applications only require gauge pressure. Understanding the details of an application can make selecting an appropriate pressure sensor easy. Below are a few of the most commonly referenced types of pressure.

Gauge pressure (psig) references the atmosphere around the sensor, or ambient air pressure. Simply put, it is the absolute pressure minus the atmospheric pressure. The sensing element has a deflection due to a pressure change, and therefore a reference point is required to identify exactly the pressure that is being measured. Pressure sensors that use gaugep (usually psig, barg, and kpag) include a vent. This vent can be built in to the sensor itself, or through a tube in the electrical connection. The vent is positioned to use atmospheric pressure as a reference point for the sensor to measure the media, so when the pressure port is exposed to the atmosphere, the sensor will read 0 psig. Using gauge pressure ensures that at any location in the world, the sensor will always reference the location in which it is installed.

A look at different types of pressure

While gauge pressure is measured from atmospheric, absolute pressure (psia) is measured from absolute zero pressure, so when the pressure port is exposed to the atmosphere the sensor will indicate atmospheric pressure (approx. 14.7 psia). Absolute pressure uses a full vacuum as its reference — it is the gauge pressure of the media plus the pressure of the atmosphere. In different locations and elevations, the reference point can change because of atmospheric pressure variations. The atmospheric pressure varies with temperature and altitude above sea level. An absolute pressure sensor eliminates the reference to varying atmospheric pressure and relying on a specific pressure range for reference.

Sealed pressure (psis) is referenced to the prevailing atmospheric pressure which is hermetically sealed in the chamber within the sensor. No venting is needed because the reference point is pre-determined. When the pressure port is exposed to ambient atmosphere the sensor will indicate 0 psi when the ambient atmosphere is identical to the sealed atmosphere. These sensors are useful in applications where it is not possible to provide a vent path, such as a depth sensor used inside a submersible vehicle with no surface vent tube, in which the sensor needs to measure depth relative to atmospheric pressure at the surface. A sealed pressure sensor can also be used to provide additional containment for high-pressure safety in case the diaphragm bursts.

Noshok differential pressure gauge

Differential pressure simply indicates the pressure difference between two pressure measurements. A differential pressure sensor is used to identify the difference between two separate pressure input ports. For example, differential pressure is used to monitor the pressure drop (or loss) from one area of an object to the other, such as pressures outside and inside a pipe, levels within a pressure vessel, before and after a barrier in a flow path, or even between two points along any flow path.

Units of pressure

psi (pounds per square inch): The unit of measure for one pound of force applied to one square inch of area — psi is the traditional unit of pressure in the imperial and US customary systems and is not part of the International System of Units (SI).

bar: One bar equals the atmospheric pressure on the Earth at sea level, which is exactly equal to 100,000 Pa. The bar unit is a metric unit of pressure, but not part of the International System of Units (SI).

Pa (Pascal): One Pascal is the International System of Units (SI) derived unit of pressure. One Pascal is defined as one newton per square meter.

In.Hg (inches of Mercury): in.Hg is defined as the pressure exerted at the base of a column of mercury exactly in. high, at gravity and 0°C (32°F). The in.Hg is not part of the International System of Units (SI) 1 in.Hg = 3.38638 kPa. In.Hg are typically used barometric pressure.

torr: A unit of pressure based on an absolute scale and is defined as exactly 1/760 of a standard atmosphere. Historically, one torr was intended to be the same as one “millimeter of mercury.” The torr is not part of the International System of Units (SI)

in.H2O (inches of water): The pressure exerted at the base of a column of water exactly 1 in. high, at gravity and 4°C (39.2°F). The in.H2O is not part of the International System of Units (SI) 1 in.H2O = 0.249082 kPa. It is typically used for a differential pressure measurement or in low pressure water applications.

Noshok

noshok.com

Filed Under: Mobile Hydraulic Tips