In the pneumatic industry, Cv is one standard for expressing the flow capacity of devices used in pneumatic systems. However, there are multiple other standards that also express flow capacity, including effective orifice size and normal liters per minute, as well as measurements of actual flow rates at specific pressure differentials. These methods are not interchangeable and even have different meanings, interpretations, and formulas from one manufacturer to another. Therefore, it is important that engineers have a solid understanding of the available data to prevent components from being oversized or undersized in pneumatic systems.

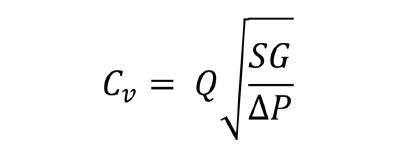

This is the basic equation for Cv, where Q is the rate of flow (gallons per minute), SG is the specific gravity of the fluid, and P is the pressure drop across the valve (psi).

It is commonly understood that nearly every pneumatic device creates a flow restriction in the system. Cv — the coefficient of flow — is one standard for expressing the flow capacity of devices used in a pneumatic system.

Many manufacturers around the world have adopted Cv as the standard value to express the flow capacity of their components. Cv is based on the volume flow rate of water at 60°F through a device within one minute at a 1 psi differential. However, there is a problem with using this equation in pneumatic applications.

Because air is compressible, Cv must have additional factors built into the equations to compensate for that compressibility. For pneumatic applications, Cv should be calculated by referencing the appropriate equation and conditions outlined in the ANSI/NFPA T3.21.3 specification. When doing so, it is important to observe proper test conditions. This includes ensuring that pressure upstream of the component being tested is a nominal 95 psia, and that the differential between the upstream and downstream pressure of the component being tested is 1 psi.

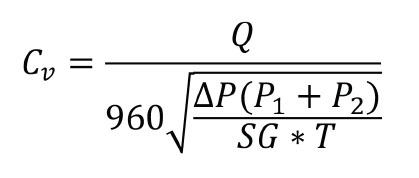

This example shows how one manufacturer deviates from the ANSI/NFPA standard with their Cv calculation. Here, Q is the rate of flow (standard cubic feet per hour), ΔP is the pressure drop across the valve (psi), P1 is the inlet pressure (psia), P2 is the outlet pressure (psia), SG is the specific gravity of the fluid at standard atmospheric pressure (60°F and 14.7 psia), T is the absolute temperature Rankine (°F + 460).

It is important to note that not every manufacturer expresses the flow capacity of their valves as Cv based on the ANSI/NFPA specification. For example, the nearby equation is the calculation used by one manufacturer. The constant in the equation accounts for the difference in the specific gravity of air versus the specific gravity of water. This calculation does not follow the pressure requirements of the ANSI/NFPA specification.

While the Cv method is the most popular standard, its accuracy relies on manufacturers adhering to the same test procedures. Some manufacturers test and publish Cv without any explanation of how they produce the values, while others publish explanations but fail to follow the ANSI/NFPA T3.21.3 standard.

Because Cv only looks at a 1 psi differential, the calculated flow at low pressures can be very accurate, but certain applications that have higher differentials can produce flows that do not match the calculated results. It is important to be aware that misinterpreting the Cv value can lead to differences in ratings of over 20%.

Information for this story provided by Mike Kettering, Technical Sales Specialist at Clippard Instrument Laboratory.

Filed Under: Pneumatic Tips